- Location

- Bay ridge, Brooklyn

So I read almost every week , as many of you, about new led fixtures being put on market and I'm became more and more convinced to switch from my current t5's lighting to LED. I am trying to read as much as I can before I even think of making a LED fixture myself, but from what I understand right now, it's not THAT hard to build one. I still need some advice though

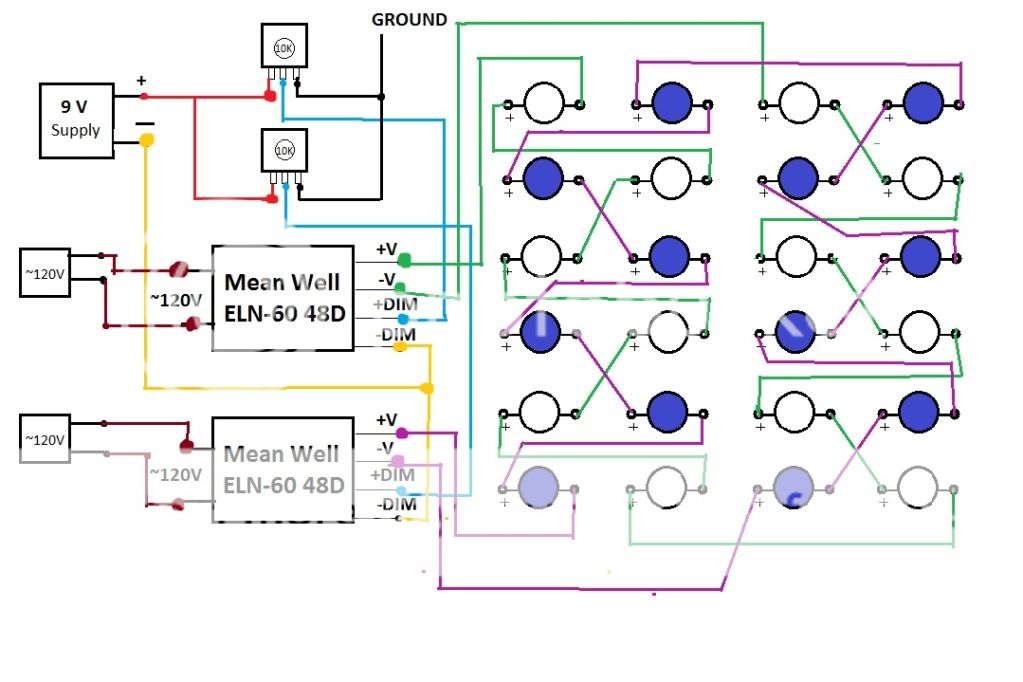

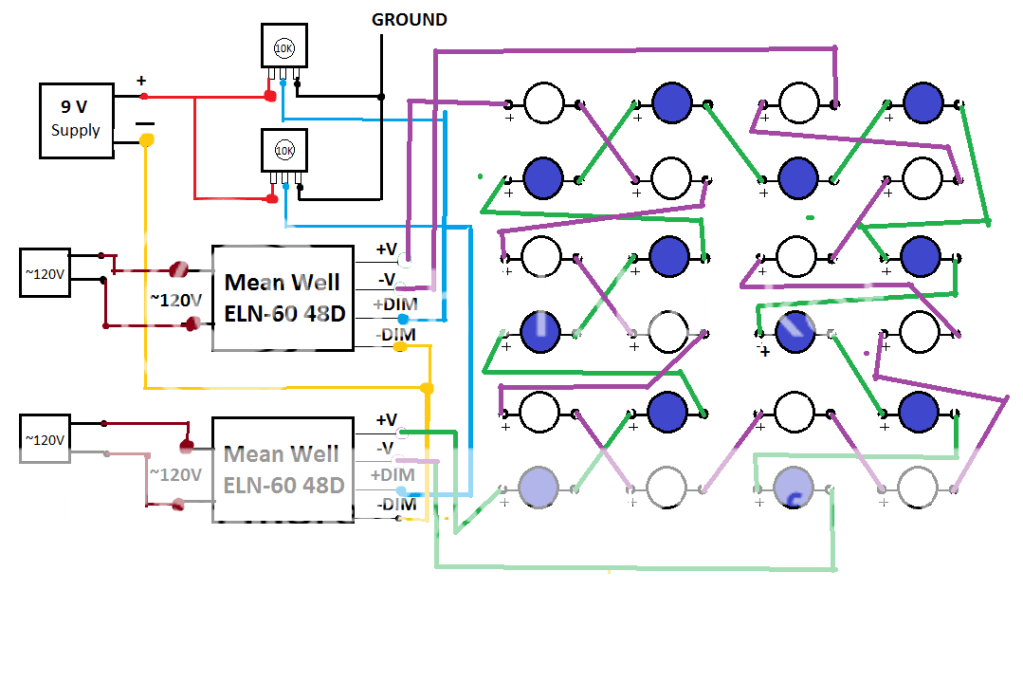

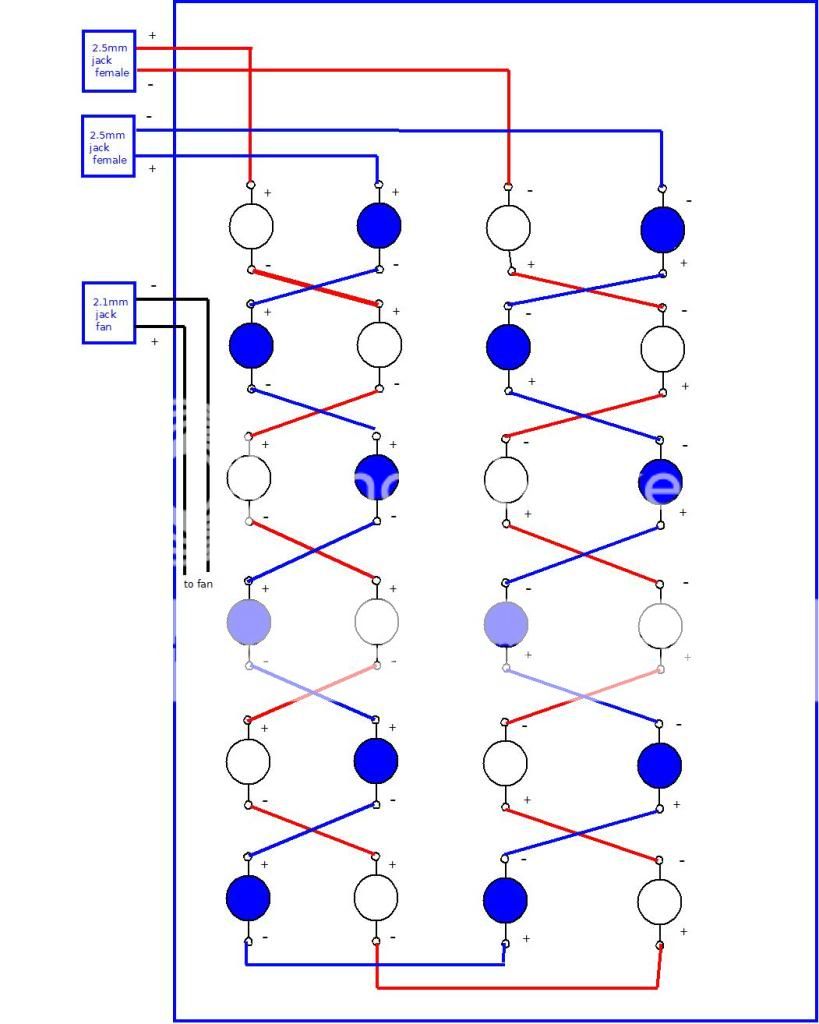

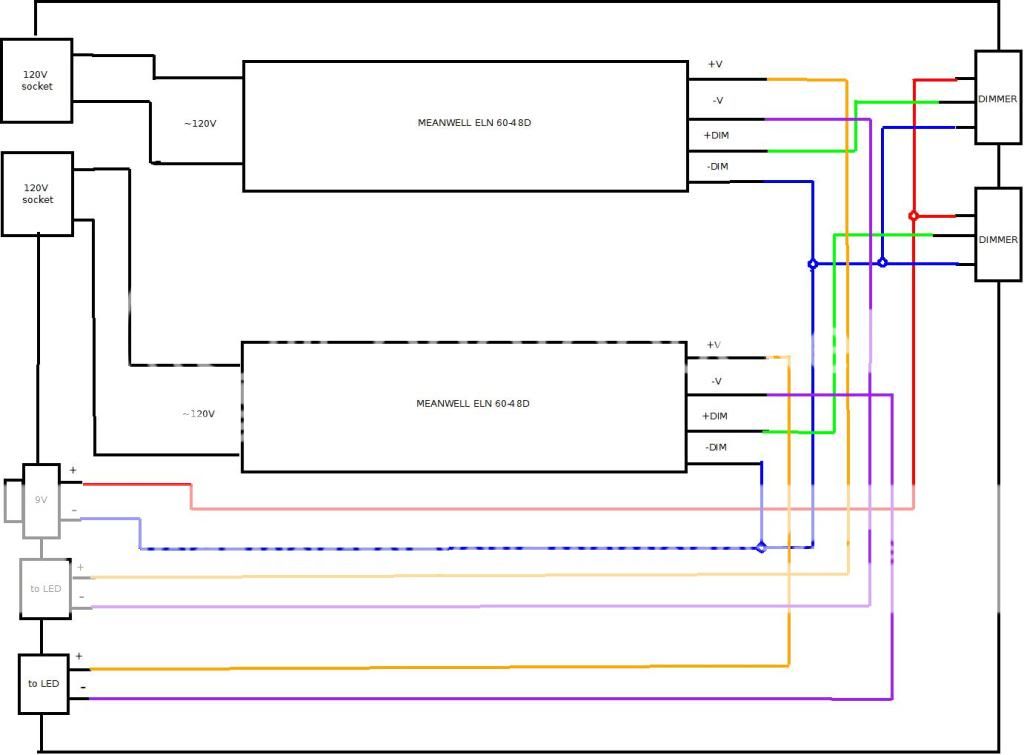

OK, let's start from the beginning- my tank is a Current Solana which has footprint of 20x20. I was thinking of buying this kit http://www.rapidled.com/servlet/the-54/24-Ultra-Premium-LED/Detail. It has 24 3W total, 12 Cool White Cree XP-G R5 LEDs, 12 Royal Blue Cree XR-E LEDs and two 48W Mean Well ELN-60-48D dimmable drivers. I have a couple of questions about them (warning, some of them may be stupid )

)

- first of all, is it a good deal or should I buy things separate

-second, even more important- is it gonna be enough light for that tank? I need to light up approximately 16x20 area (rest is back chambers) and would like to use that light also if I ever upgrade to a bigger tank (of course not by itself). Let's say that it may be an sps tank in the future, would it be sufficient? From my early calculations, the light itself would be 10x16 (2" space between leds plus 2" from the edge of housing; leds arranged in 4 rows of 6 leds, 3 white and 3 blue in each row, what do you think?)

- would you recommend a mean well driver? Correct me if I'm wrong, but does this driver need an external dc voltage source or is it built in? And one more thing, the driver is dimmable- does it mean it has a dimmer built in or do I have to solder one to it? If I have to, what kind?

That's all for now but I will definitely have more questions to come. Thank you very much for all your suggestions.

OK, let's start from the beginning- my tank is a Current Solana which has footprint of 20x20. I was thinking of buying this kit http://www.rapidled.com/servlet/the-54/24-Ultra-Premium-LED/Detail. It has 24 3W total, 12 Cool White Cree XP-G R5 LEDs, 12 Royal Blue Cree XR-E LEDs and two 48W Mean Well ELN-60-48D dimmable drivers. I have a couple of questions about them (warning, some of them may be stupid

- first of all, is it a good deal or should I buy things separate

-second, even more important- is it gonna be enough light for that tank? I need to light up approximately 16x20 area (rest is back chambers) and would like to use that light also if I ever upgrade to a bigger tank (of course not by itself). Let's say that it may be an sps tank in the future, would it be sufficient? From my early calculations, the light itself would be 10x16 (2" space between leds plus 2" from the edge of housing; leds arranged in 4 rows of 6 leds, 3 white and 3 blue in each row, what do you think?)

- would you recommend a mean well driver? Correct me if I'm wrong, but does this driver need an external dc voltage source or is it built in? And one more thing, the driver is dimmable- does it mean it has a dimmer built in or do I have to solder one to it? If I have to, what kind?

That's all for now but I will definitely have more questions to come. Thank you very much for all your suggestions.