- Location

- Sayreville, NJ

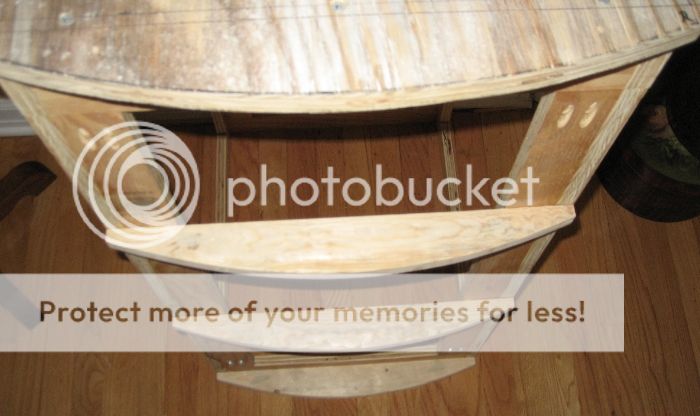

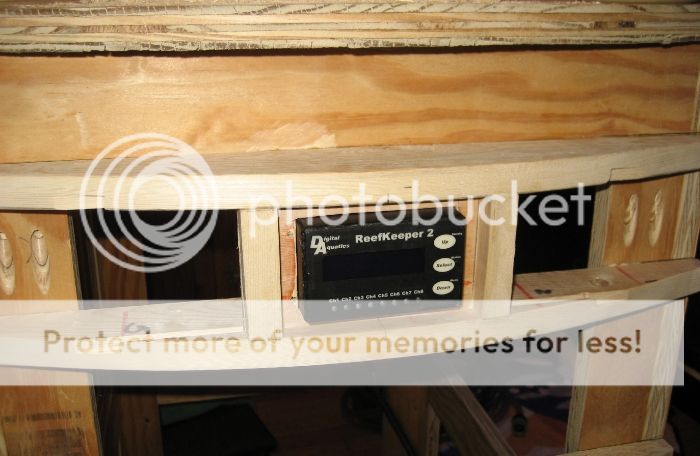

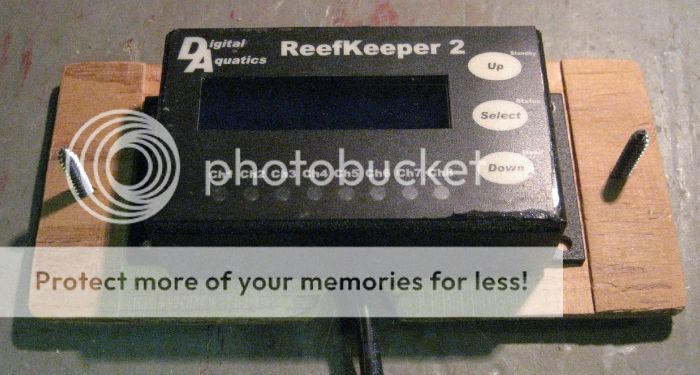

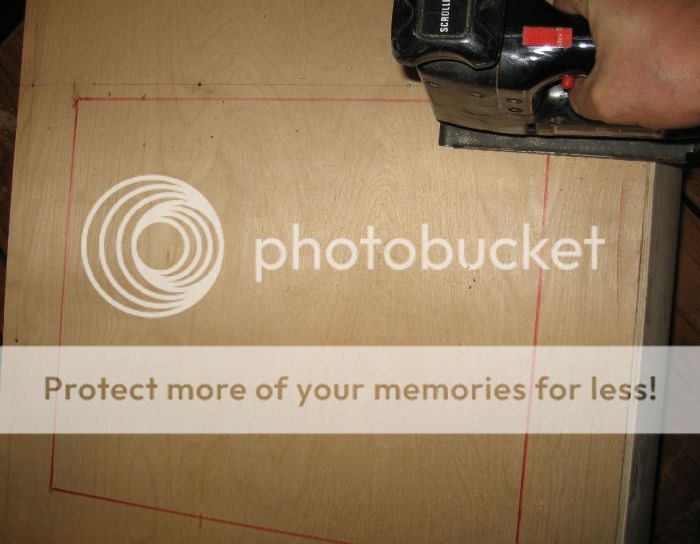

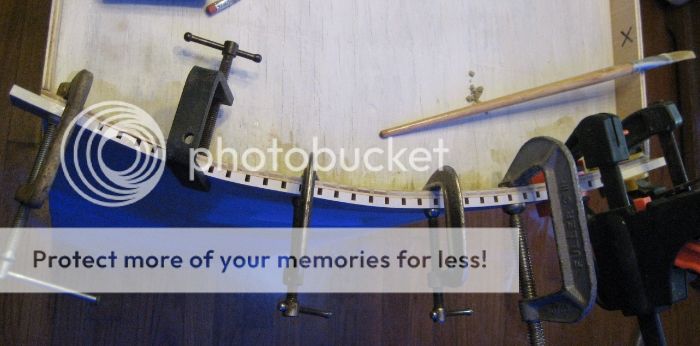

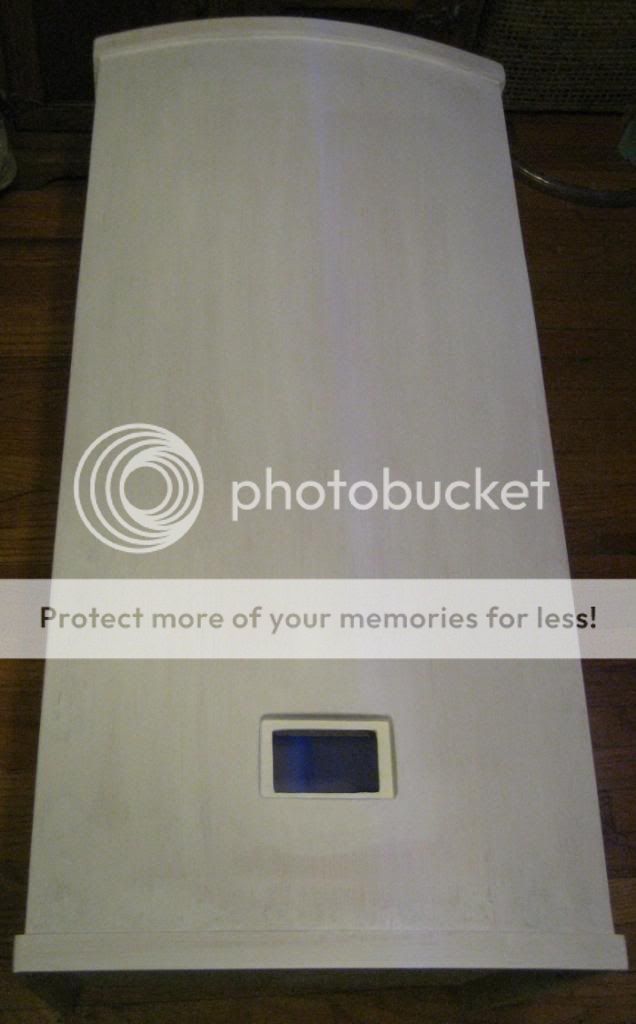

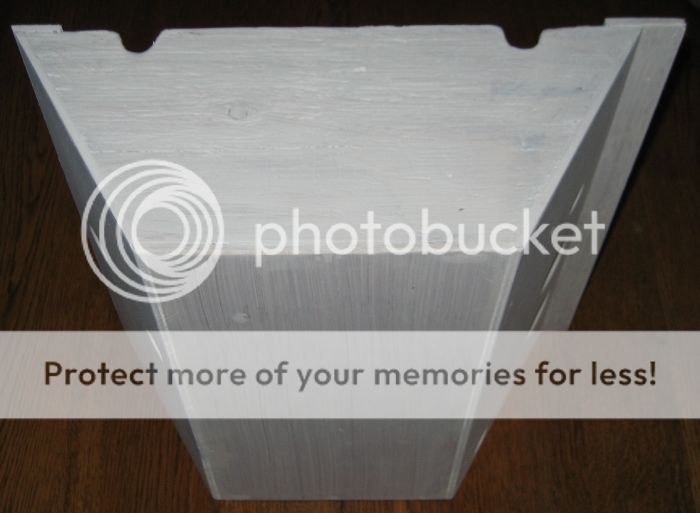

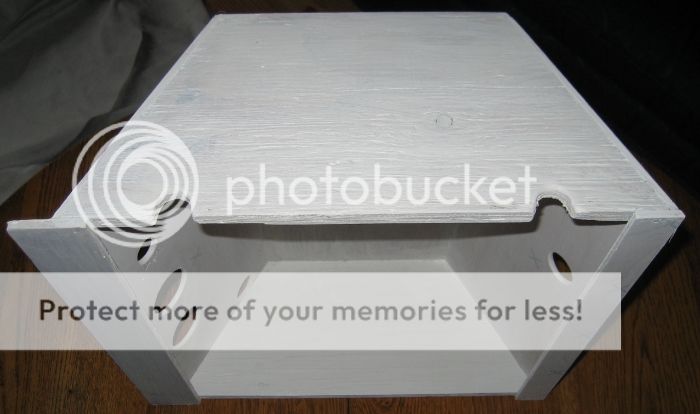

DIY JBJ-28 Nano Stand

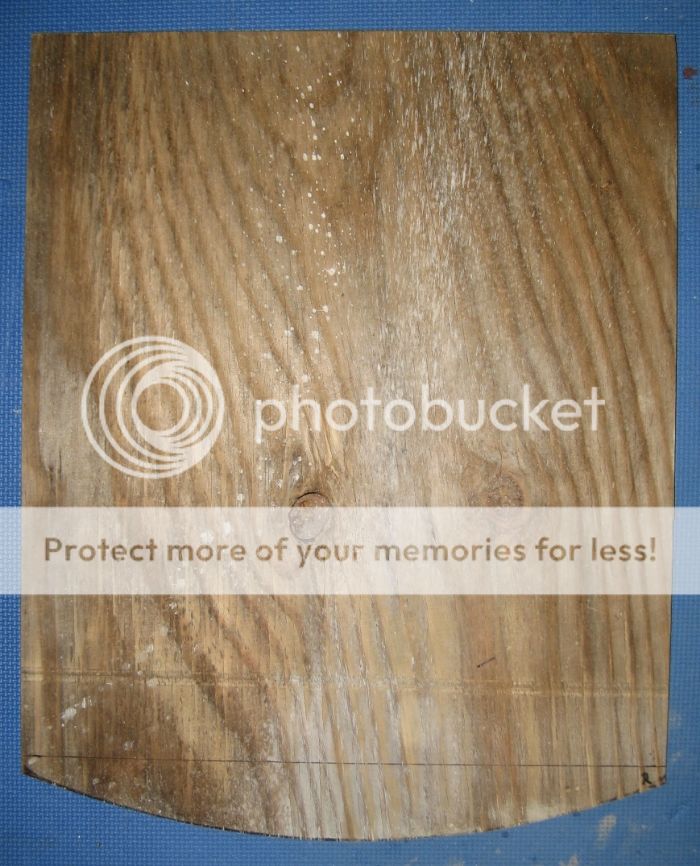

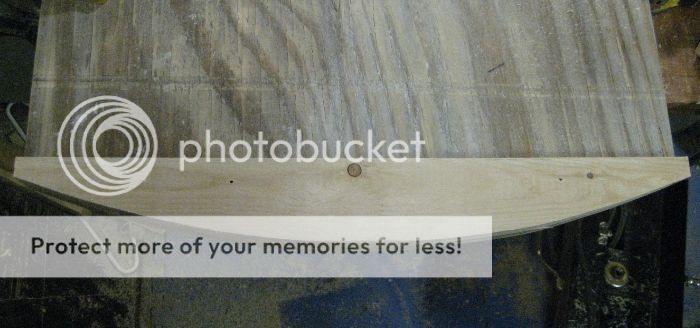

I am not overly happy with the stock JBJ stand that came with the tank so I?ve decided to build a stand of my own design with a ?bellied? front to match the belly on the tank.

Here are other specific reasons I want a new stand:

1.) I?m not real happy with the stability, or lack of stability, of the stand. When I use the MAG float to clean the front glass, the whole tank and stand sway back and forth while I push the cleaner back and forth.

2.) When I got this setup a while back, the stand never had the door installed, and therefore I did not get the door hardware. (The door wasn?t installed because the prior owner had the chiller below, and it need air flow to stay cool.)

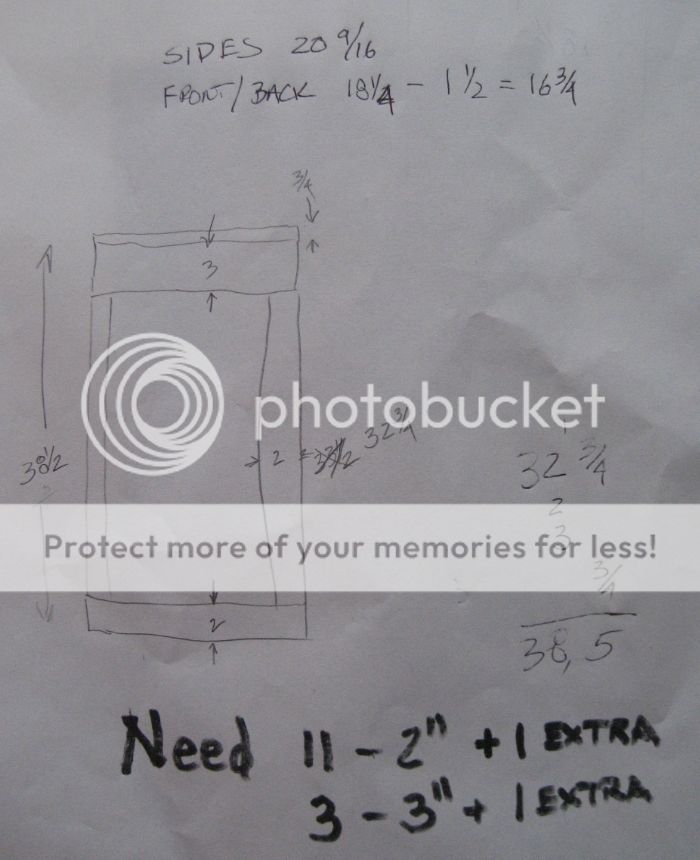

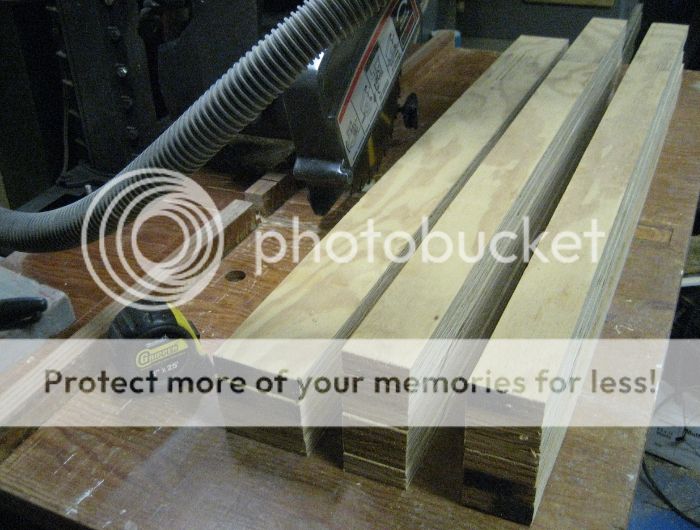

3.) I don?t like standard height stands?.they are too low?..32 inches. I have to bend down to look into the tank. This new build will be approximately 38 ? inches high.

4.) More storage. They built that current stand to have ?style,? with the narrow sides, and floating top?but it grossly limits storage.

I am not overly happy with the stock JBJ stand that came with the tank so I?ve decided to build a stand of my own design with a ?bellied? front to match the belly on the tank.

Here are other specific reasons I want a new stand:

1.) I?m not real happy with the stability, or lack of stability, of the stand. When I use the MAG float to clean the front glass, the whole tank and stand sway back and forth while I push the cleaner back and forth.

2.) When I got this setup a while back, the stand never had the door installed, and therefore I did not get the door hardware. (The door wasn?t installed because the prior owner had the chiller below, and it need air flow to stay cool.)

3.) I don?t like standard height stands?.they are too low?..32 inches. I have to bend down to look into the tank. This new build will be approximately 38 ? inches high.

4.) More storage. They built that current stand to have ?style,? with the narrow sides, and floating top?but it grossly limits storage.